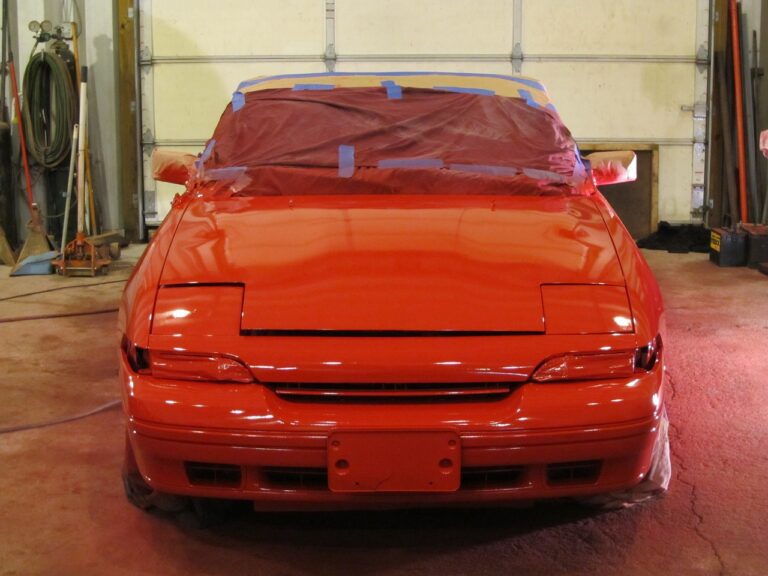

The Impact of 3D Printing on Car Restoration Projects

3D printing technology has revolutionized the way car restoration projects are approached. Its ability to create custom and intricate parts with precision has significantly aided in the restoration of vintage and classic cars. Traditional methods often faced challenges in reproducing rare or discontinued parts, but with 3D printing, these obstacles are easily overcome.

Moreover, the cost-effectiveness of 3D printing in car restoration projects cannot be understated. By utilizing this technology, car enthusiasts and restoration professionals can save both time and money by eliminating the need for expensive molds or tooling. The flexibility of 3D printing allows for quick iterations and adjustments, ensuring that the final restored car meets the desired specifications without breaking the budget.

History of 3D Printing in Automotive Industry

3D printing technology has been making significant strides in the automotive industry over the years. With its roots tracing back to the 1980s, the introduction of 3D printing revolutionized the way car parts are designed and produced. At first, 3D printing was primarily used for prototyping purposes, allowing designers to quickly create physical models of their concepts before moving to mass production.

As the technology advanced, automotive manufacturers started to explore the possibilities of using 3D printing for producing end-use parts in cars. This shift towards utilizing 3D printing in the production of actual components led to improvements in efficiency, cost-effectiveness, and customization options in the automotive sector. Today, 3D printing has become an integral part of car restoration projects, providing restoration enthusiasts with the means to recreate rare and obsolete parts that are no longer in circulation.

What are the benefits of utilizing 3D printing in car restoration projects?

Some benefits include the ability to create custom and hard-to-find parts, reduced lead times for production, cost-effectiveness for low-volume production, and the ability to quickly iterate and test designs.

What is the history of 3D printing in the automotive industry?

3D printing has been used in the automotive industry since the 1980s for prototyping and tooling. Over the years, advancements in technology have allowed for the production of end-use parts, leading to increased adoption by car manufacturers.

How has 3D printing revolutionized car restoration projects?

3D printing has made it easier to restore classic cars by providing a way to reproduce obsolete or rare parts that are no longer in production. This technology has allowed restoration enthusiasts to bring vintage vehicles back to life with greater ease and accuracy.